The "Waste to Wood" Revolution

Transforming millions of discarded oil palm trees into high-quality, fire-resistant wood products through innovative processing technology.

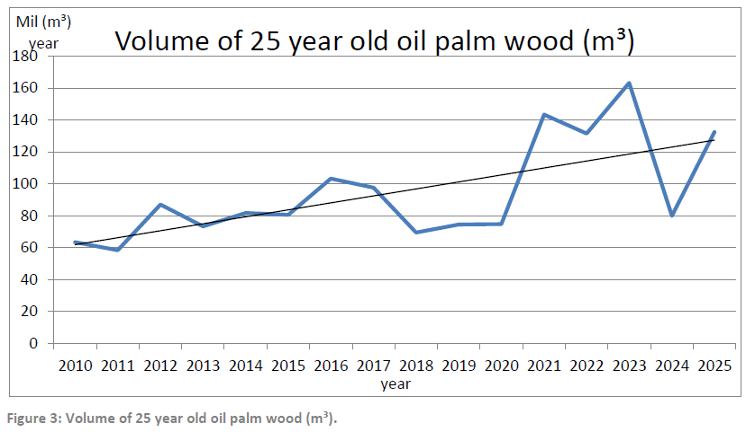

Global Oil Palm Biomass Projection

Projection of global oil palm trunk biomass volume from 2010-2025 (Kurz, 2013)

The Problem: A Mountain of Waste

Every year, millions of oil palm trees reach the end of their productive lives. After roughly 25 years, they produce significantly fewer fruits, and farmers must cut them down to make way for new saplings.

This results in a staggering amount of biomass waste across Thailand, Indonesia, and Malaysia. Instead of letting these trunks rot or be destroyed, we see them as a valuable resource waiting to be unlocked.

Environmental Impact

- • Millions of palm trees discarded annually

- • Massive biomass waste accumulation

- • Lost opportunity for carbon capture

- • Environmental degradation from waste

Wasted Oil Palm Trees Worldwide

Millions of discarded oil palm trees across different countries represent untapped potential

The eradication of oil palm trees for replanting, which is common in the southern region, involves cutting the base of the oil palm trees

and injecting chemicals into the trunks to kill them in Krabi province

The eradication of oil palm trees for replanting in Indonesia is carried out in a similar manner to that in Thailand, namely by cutting the base of the oil palm trees

and injecting chemicals into the trunks to kill them (Erwinsyah, 2008)

The eradication of oil palm trees for replanting in Malaysia is carried out in the same manner as in Thailand by cutting the base of the oil palm trees (MPOB, 2011

Sustainable Transformation

- • Convert waste into valuable wood products

- • Utilize spare capacity of local sawmills

- • Comprehensive carbon footprint analysis

- • Create new revenue streams for farmers

The Solution: A New Life for Palm Wood

Our project intercepts this waste and transforms it into high-quality, usable wood products. We're launching a new business operation to produce processed, dried palm oil wood by utilizing the spare capacity of local rubberwood sawmills.

All processes include detailed carbon footprint analysis to ensure maximum sustainability. Our goal is to develop and market a range of downstream products that meet modern demands.

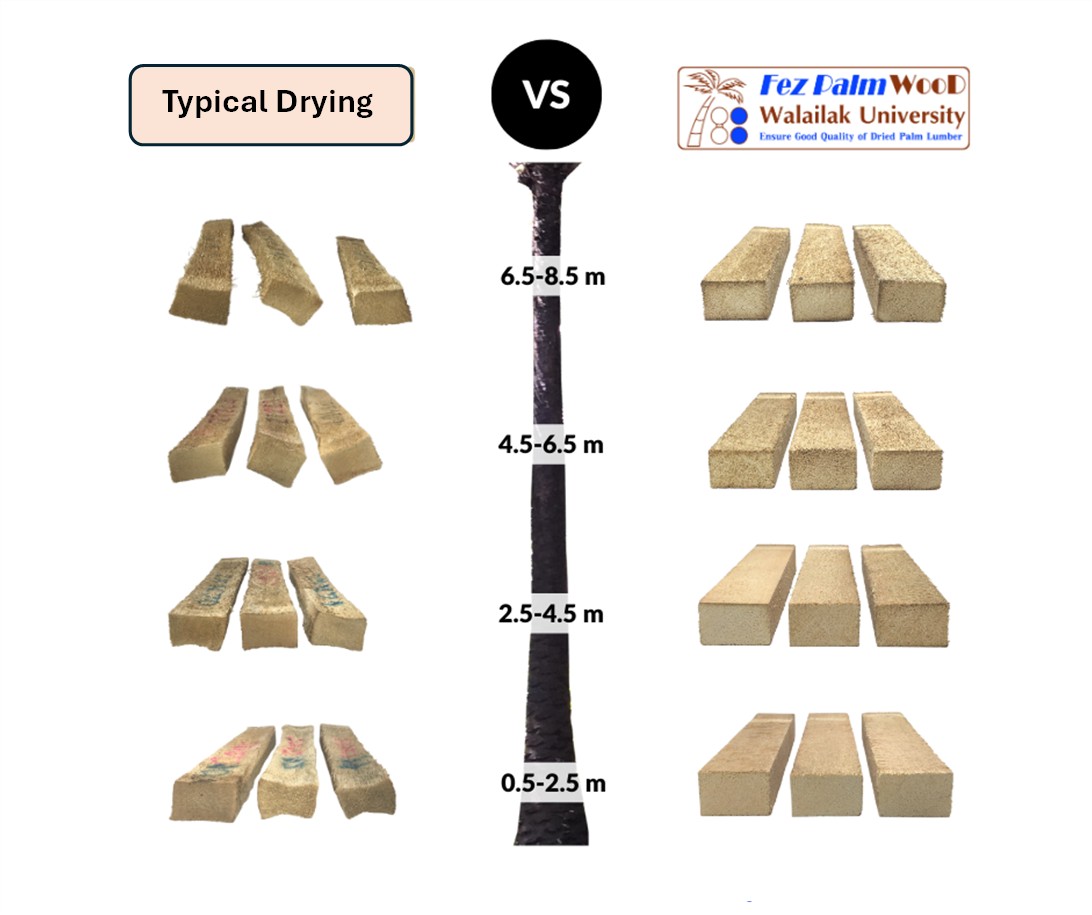

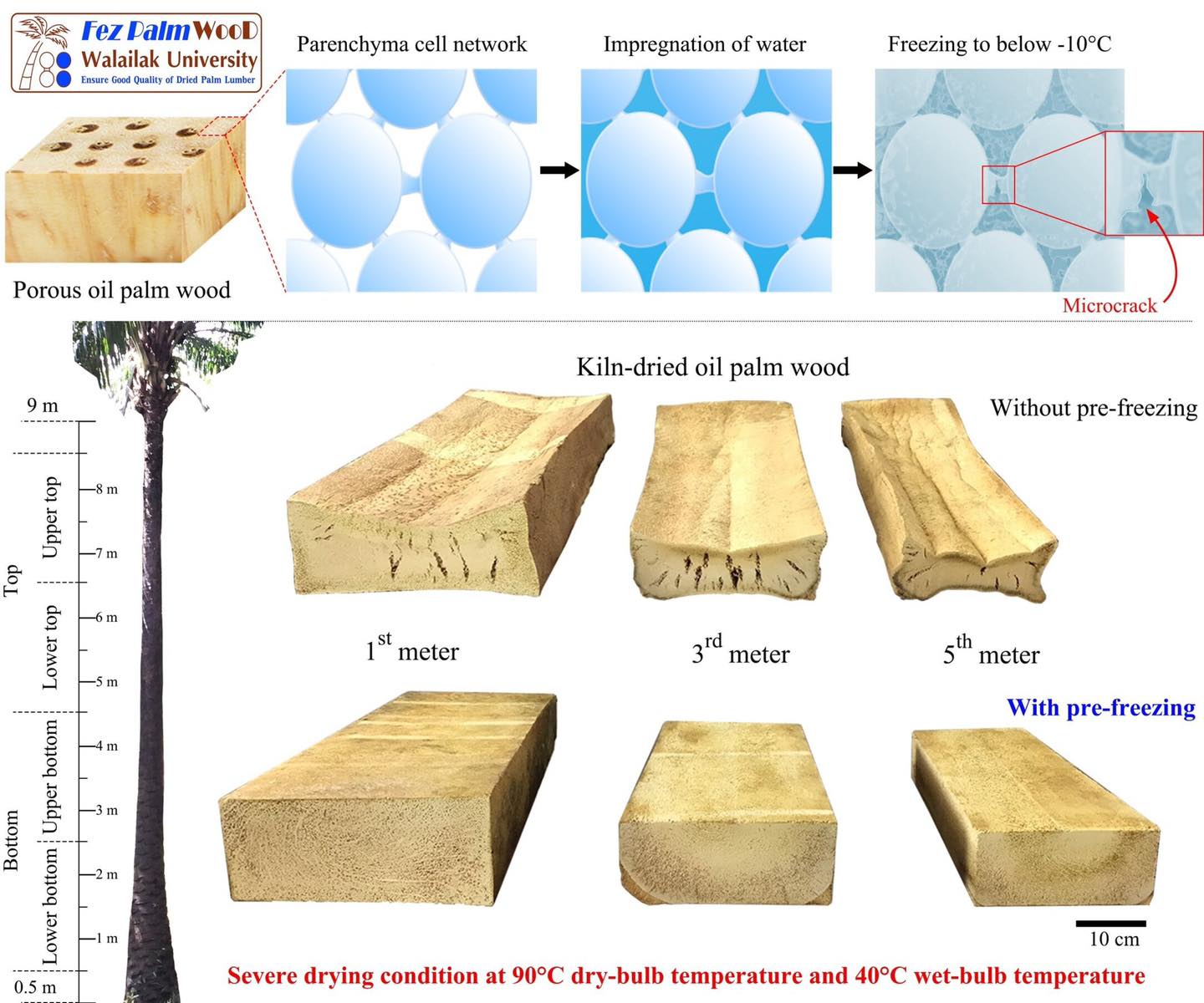

Palm Wood Processing Technology

Our proprietary process transforms raw palm trunks into stable, high-quality wood

Complete processing workflow from raw palm trunk to finished stable wood product

Project Objectives

Our comprehensive approach to transforming palm oil waste into valuable wood products

Production Plant Design

Design a proprietary palm wood pilot production plant at Walailak University with cutting-edge technology.

Business Operations

Start business operations producing processed dried palm oil wood using local sawmill capacity.

Market Development

Develop downstream products from processed palm wood to meet specific market demands.

Our Innovations

Pioneering new technology to create stable, fire-resistant palm wood products

AICA ARMOR Fire-Resistant Technology

How we incorporate AICA ARMOR to create fire-resistant palm wood

Patented Stabilization Process

We've developed and patented a proprietary process to create stable palm wood, preventing material collapse during drying for durable, reliable lumber.

Fire-Resistant Technology

By incorporating AICA ARMOR fire retardant, we've created fire-resistant palm wood with publicly demonstrated impressive fire resistance capabilities.

Key Advantages

- Unique wood grain perfect for various applications

- Enhanced safety through fire resistance

- Sustainable alternative to traditional lumber

- Cost-effective production process

Fire-Resistant Palm Wood Products

Demonstrating the exceptional fire-resistant properties of our treated palm wood

Fire-resistant palm wood door

Unique palm wood grain texture

Fire Resistance Demonstrations

Public demonstrations proving the exceptional fire-resistant properties of our palm wood